Fan Filter Unit System

Biopharmaceutical manufacturing in aseptic environments demands strict contamination control.

Becarv’s Fan Filter Unit (FFU) system introduces high-efficiency air filtration and laminar flow into existing rooms, quickly and without structural modifications. Downtime is minimal, making it a fast, cost-effective upgrade for cleanroom compliance.

What is a Fan Filter Unit?

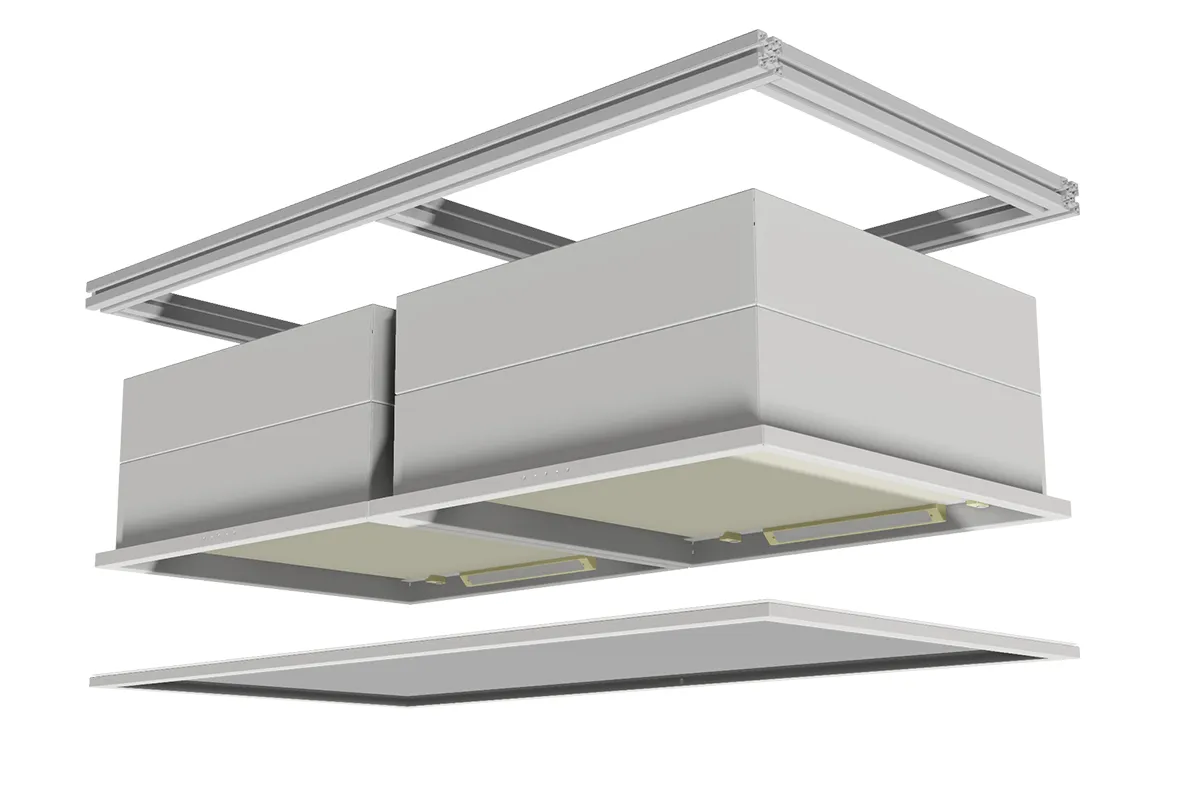

A Fan Filter Unit (FFU) is a self-contained module that houses a fan and a High-Efficiency Particulate Air (HEPA) or Ultra-Low Penetration Air (ULPA) filter within a compact casing. It pulls in ambient air, removes particles, microbes and dust, and delivers clean air downward in a laminar flow to maintain a controlled environment.

Its simple maintenance and low operating cost make it ideal for cleanroom-critical applications.

Key Features & Benefits of Becarv FFU Technology

1. Superior Containment & Compliance

- Patented gel-seal technology ensures airtight performance and meets top biosafety classifications

- 316L stainless steel resists aggressive cleaning agents

- Fully compliant with current Good Manufacturing Practices (cGMP)

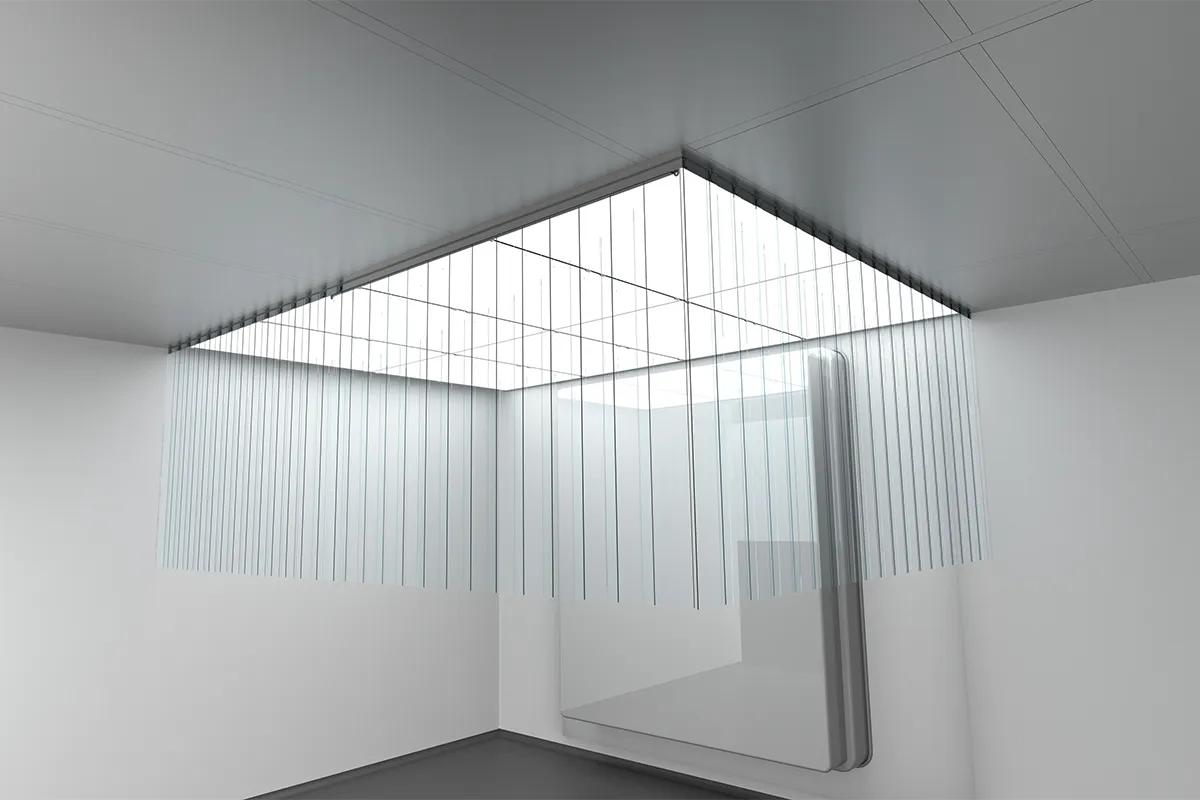

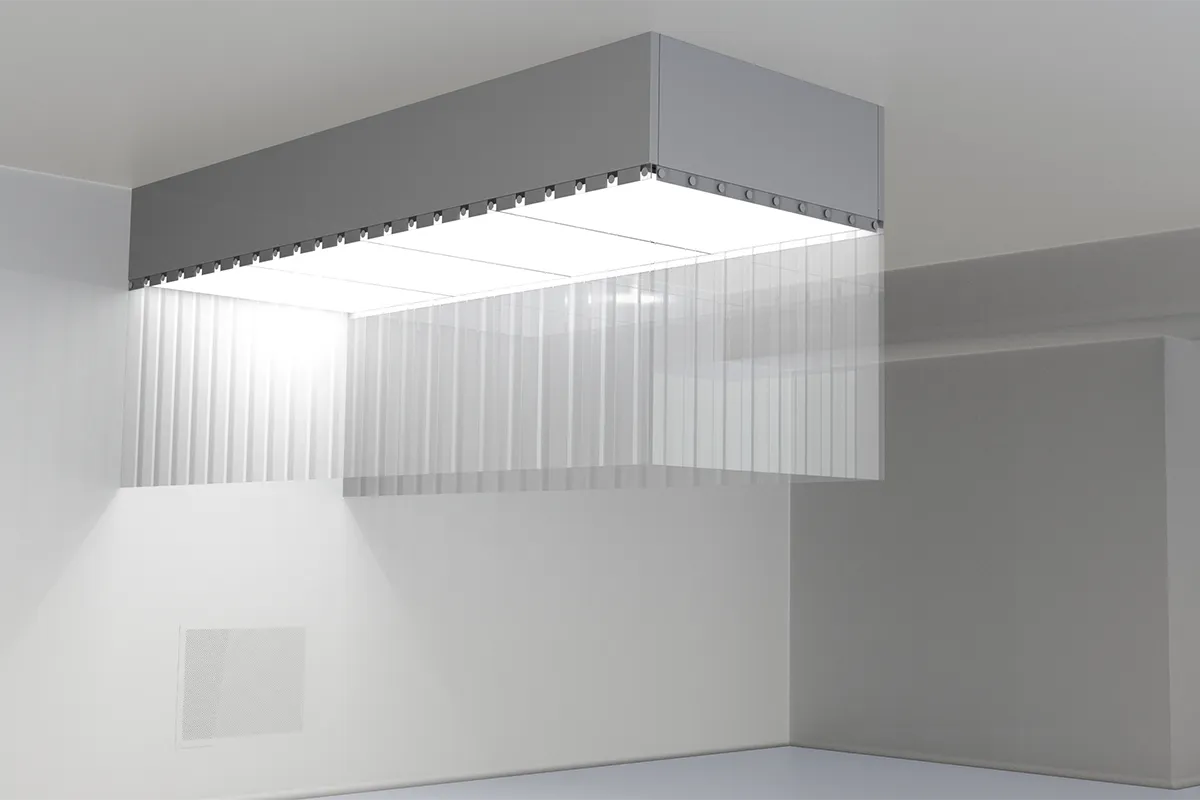

2. Modular Design & Flexible Integration

- Available in multiple sizes: from compact FFUs to high-performance models

- Scalable architecture supports future production expansion

- Clip-on filters and standardized frames reduce installation and qualification time

3. Operator Comfort & Workspace Optimization

- Ultra-quiet fans reduce noise fatigue for operators

- Integrated LED lighting (≥ 500 lux) with dimming for task precision

- Plexiglass guides or PVC curtains (fixed or sliding) optimize airflow confinement without restricting mobility

4. Smart Performance & Energy Efficiency

- Built-in regulator ensures consistent, compliant airflow by auto-adjusting fan speed in real time

- Electronically commutated (EC) motors reduce energy use and heat output

- Quiet, durable, and ideal for continuous-use settings like pharmaceutical and biotech production lines

5. Low Maintenance & Long Lifecycle

- Tool-free filter replacement by in-house teams keeps downtime low

- Long-life filters, extended warranties, and optional service plans help control total cost of ownership

Why choose Becarv’s FFU?

At Becarv, we engineer every FFU with three core principles in mind:

High quality, intelligent design, and cost efficiency

Our modular Fan Filter Units are built to streamline cleanroom upgrades by:

- Reducing build schedules

- Minimizing installation downtime

- Fitting seamlessly into existing ceiling spaces, even in tight environments

Engineered for High-Performance Cleanroom Integration

- Compact, modular design allows effortless retrofitting without major layout changes

- Patented gel-seal system ensures airtight containment for maximum biosafety compliance

- All high-contact surfaces are made from 316L stainless steel, providing:

- Superior resistance to corrosive cleaning agents

- Long-lasting structural integrity

- Clip-on filter mechanism enables fast, tool-free filter replacements by in-house teams

- Optional integrated cooling unit helps reduce heat gain in the cleanroom, maintaining thermal stability and protecting temperature-sensitive products

Typical FFU Applications

Becarv FFUs are ideal for installation in a variety of critical environments:

- Between washing and wrapping stations

- Above unloading zones at washing stations (pre-storage)

- In controlled storage rooms requiring particulate-free air

- Above sterilization or post-sterilization unloading areas

- Above packaging zones (pre-sterilization or irradiation steps)

- In fully controlled environments where continuous laminar airflow is required

Need to combine FFU technology with existing HVAC systems?

Discover our Hybrid Airflow Solution, the flexible way to extend clean airflow without overloading your infrastructure.